Production-Grade Materials for Industrial FDM® Platforms

Developed for high-performance industrial FDM production, with a focus on process stability, material consistency, and repeatable results across platform-specific 3D printers.

NEXT 3DP

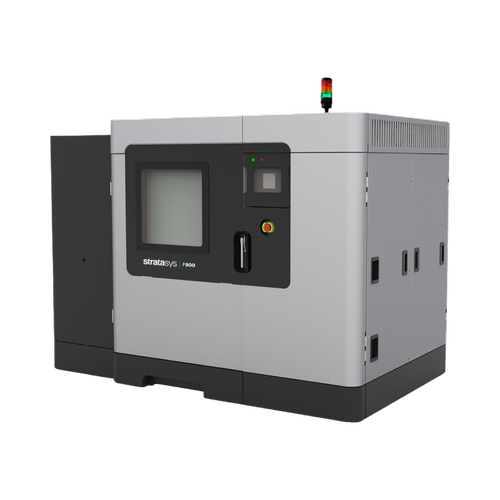

Stratasys® Fortus® Compatible Materials

Model and support materials for Fortus® systems, including ABS-M30®-class alternatives and high-temperature polymers such as ULTEM™ 9085 and ULTEM™ 1010. Use the pricing tools, cost calculators, and setup guides below to compare materials, estimate part cost, and plan production builds on Fortus® 360mc, 400mc, 450mc, 900mc, and F900 platforms.

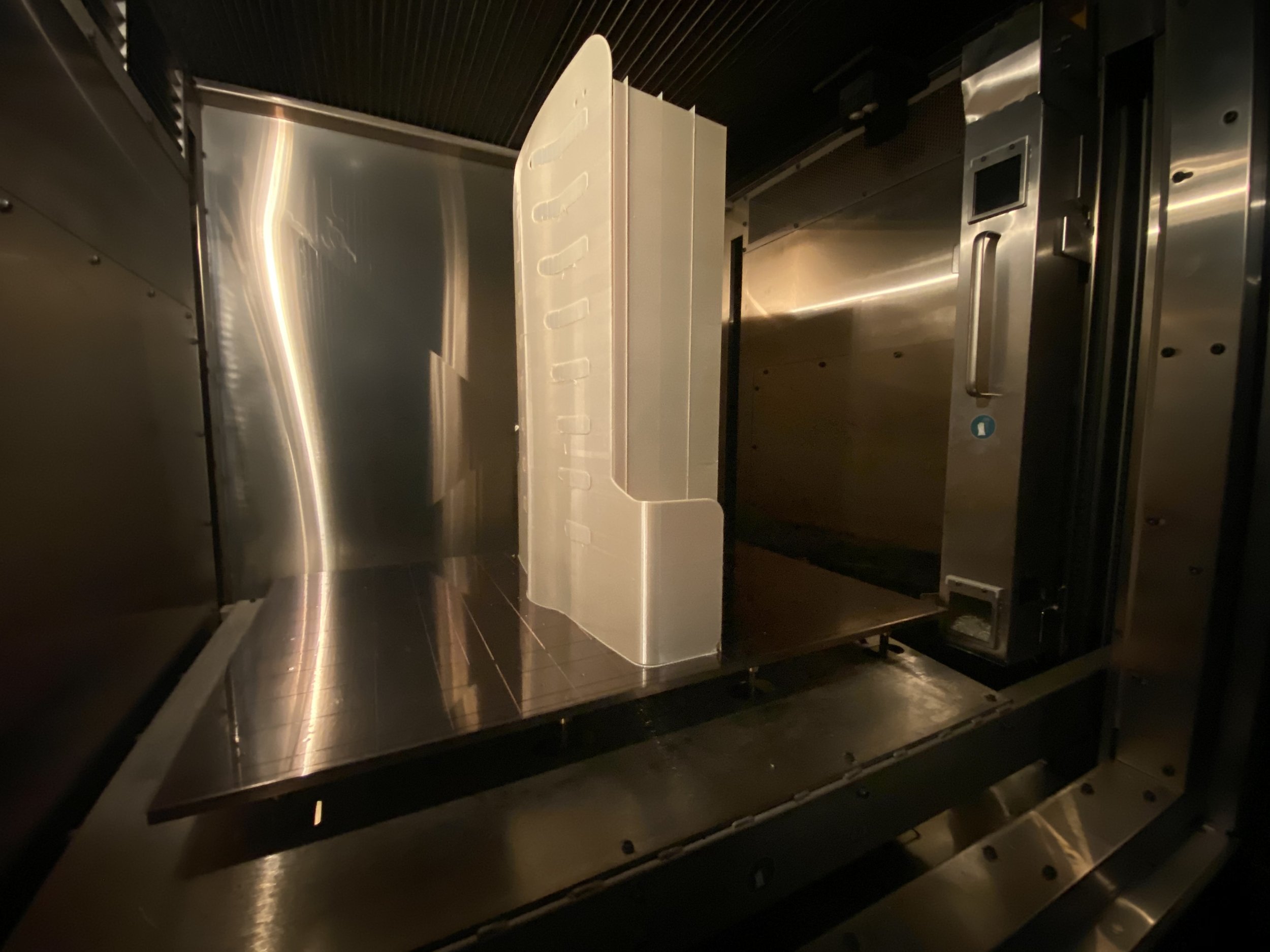

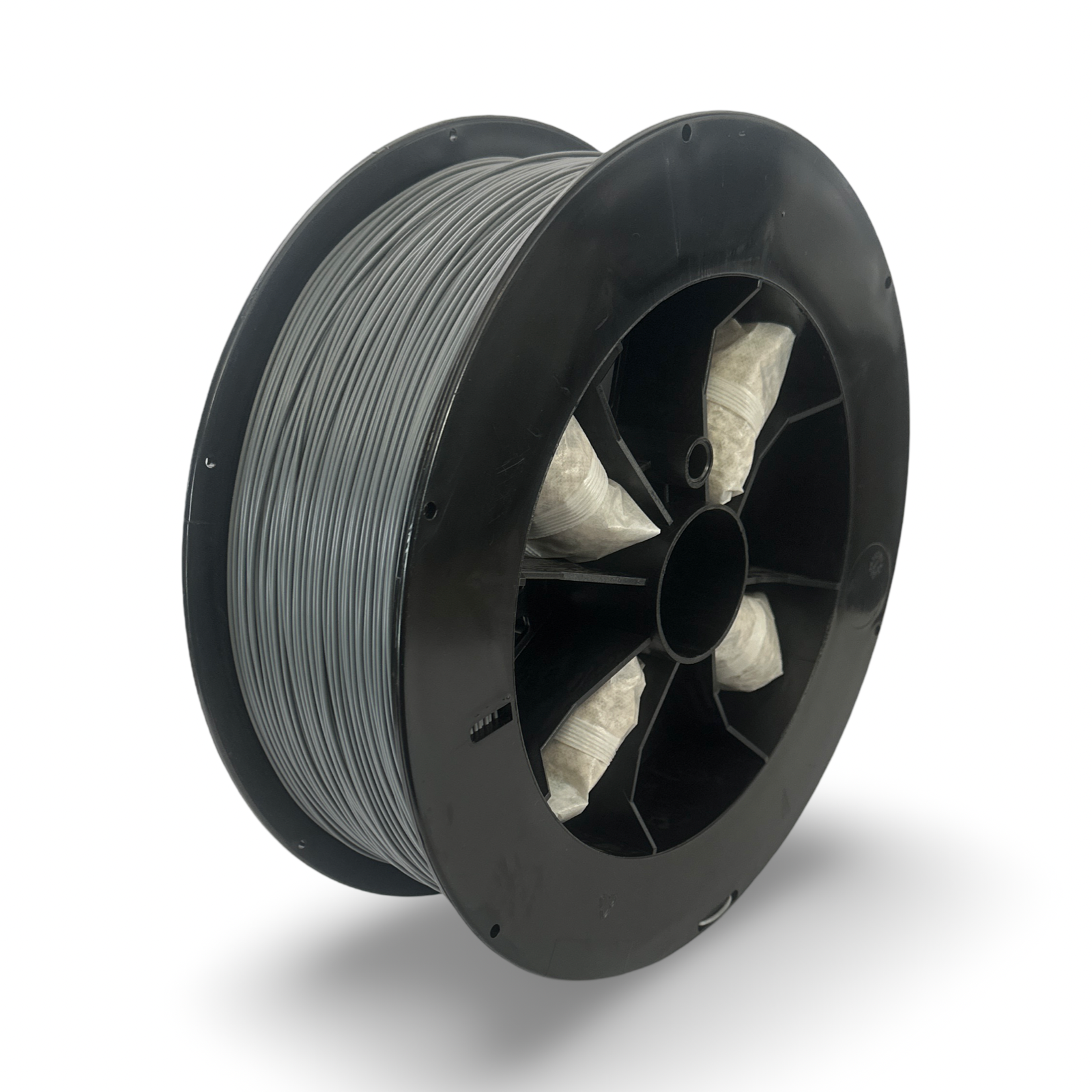

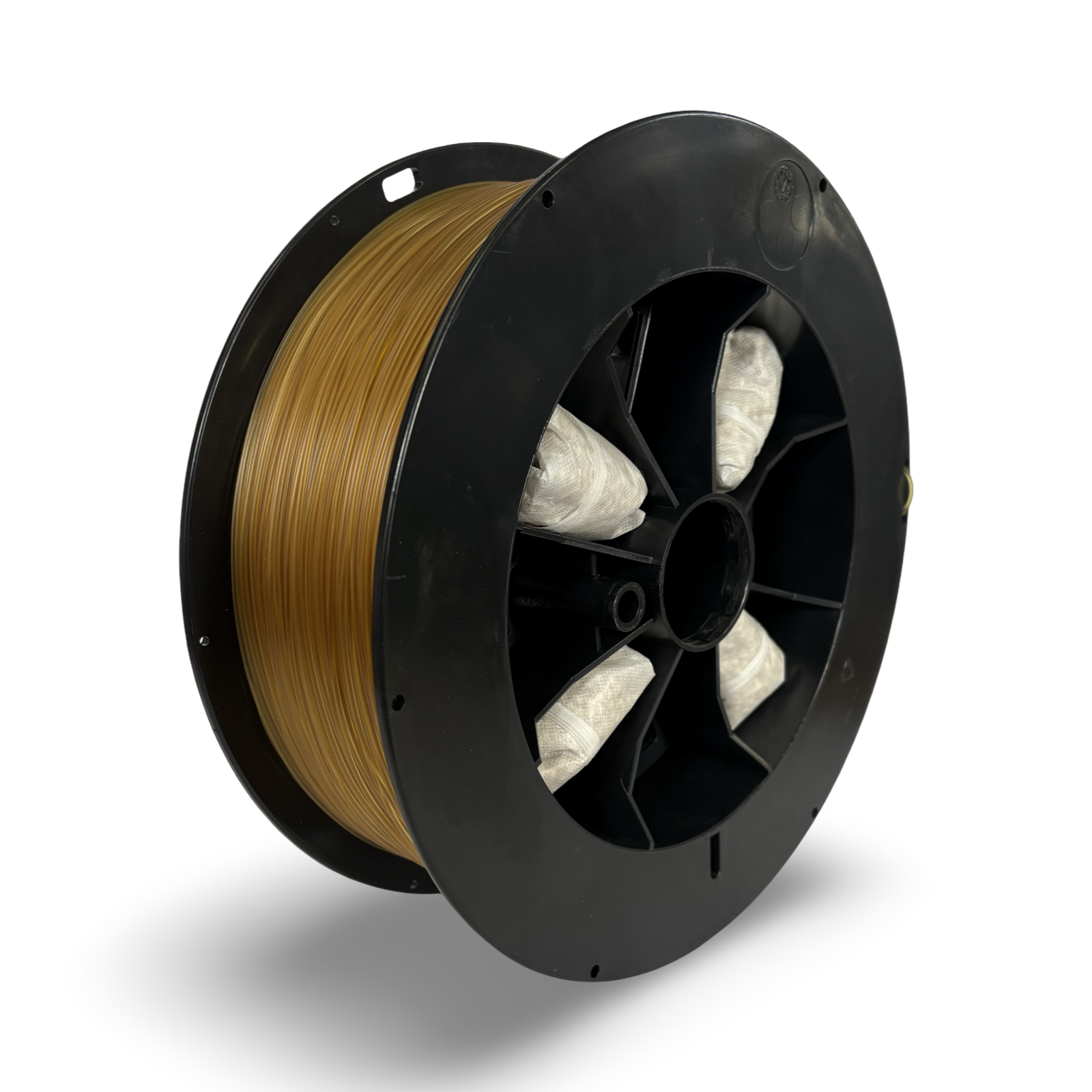

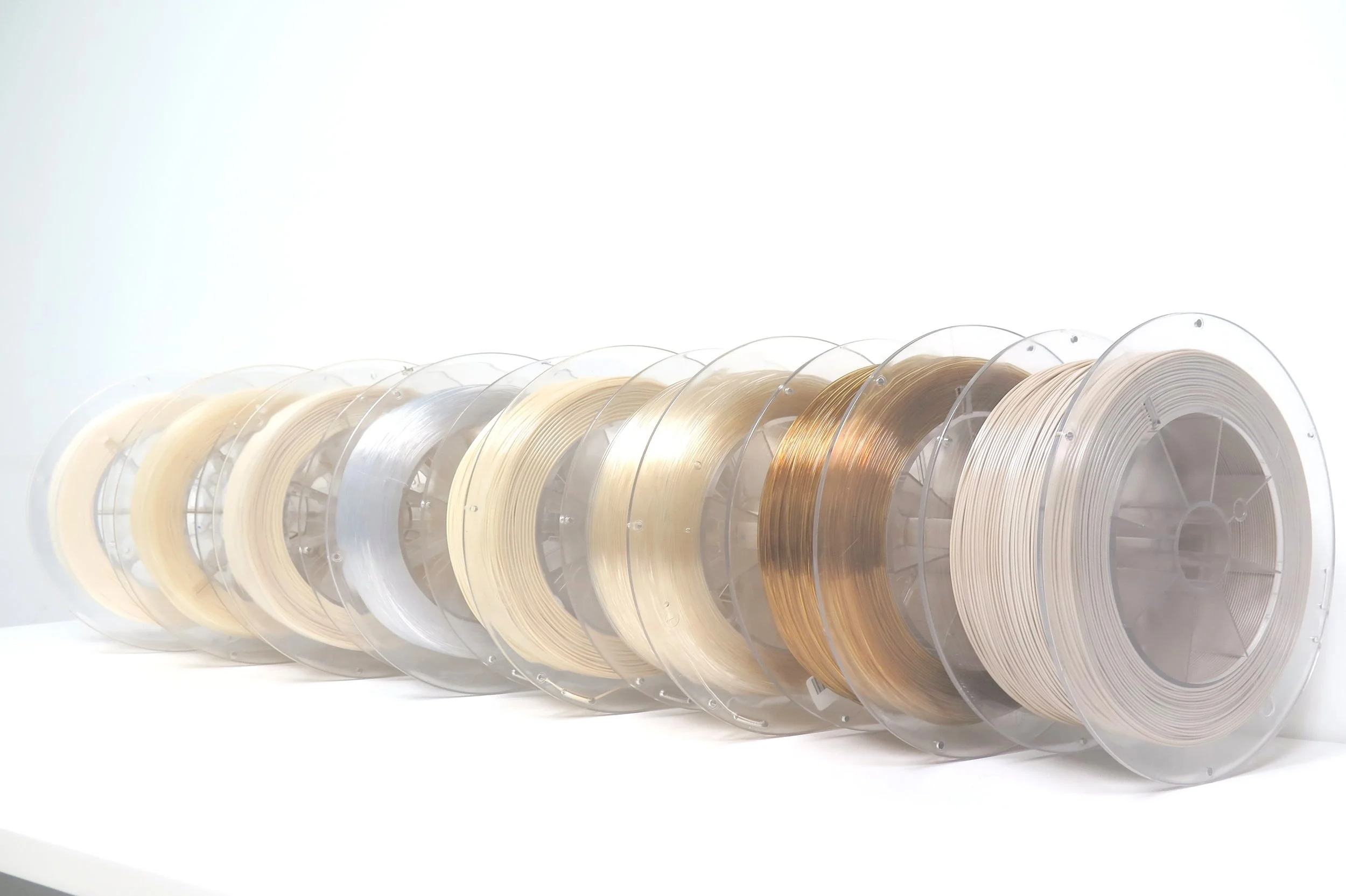

Extrusion + Packaging

Precision diameter control and moisture-managed packaging using heat-sealed Mylar® barrier bags with molecular sieve desiccant. Prepared for immediate installation and consistent performance in Fortus® canister systems.

Plug-and-play focus

Developed for Fortus® process conditions (oven + setpoints) using production-grade resin families with lot traceability and controlled formulation — aligned with ABS-M30®-class and ULTEM™ 9085 / 1010 material requirements.

Production Expertise + Backing

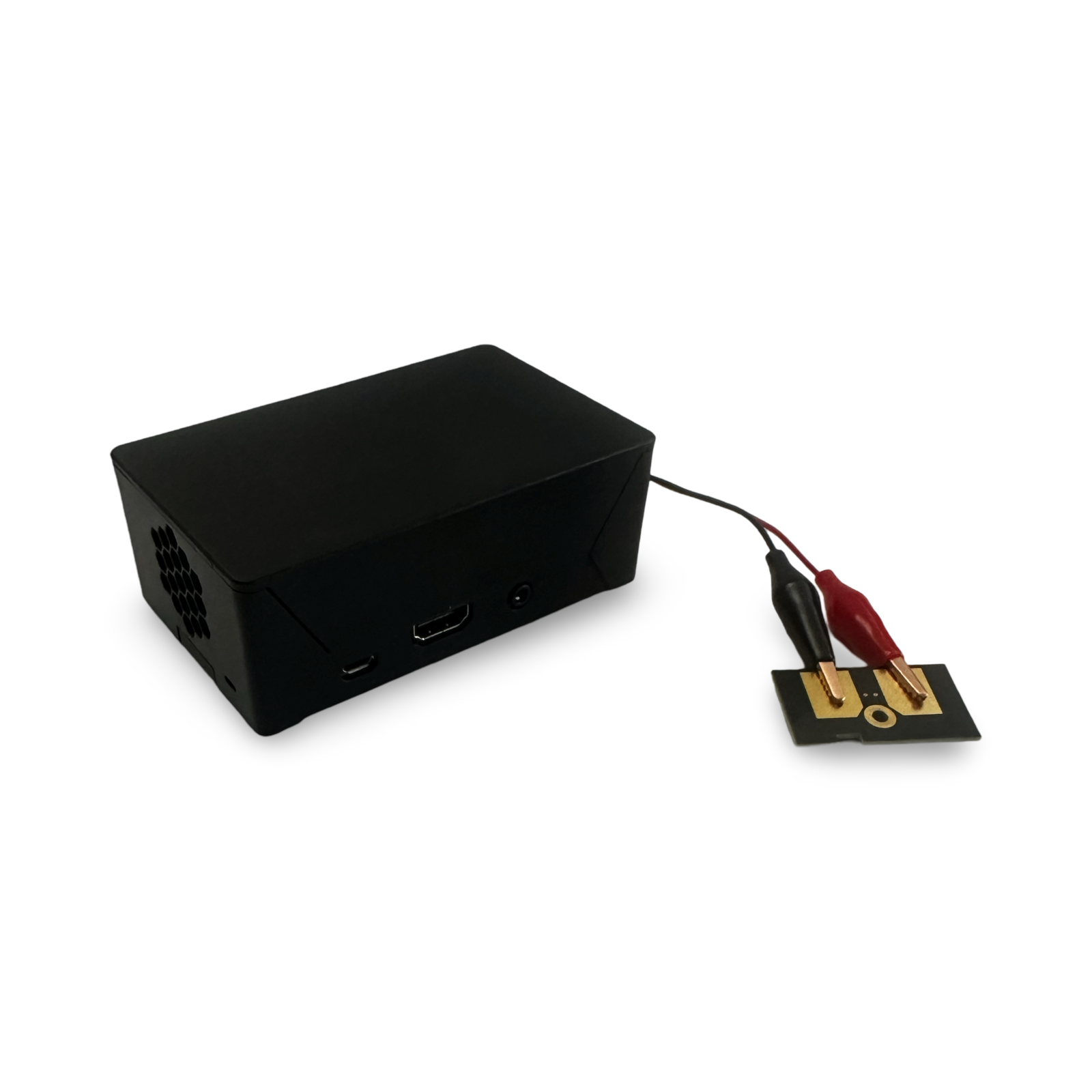

Extensive system-level knowledge, EEPROM writing tools, and Fortus® parameter guidance — supporting material integration, platform setup, and stable, repeatable production performance.

Popular resources for Fortus® users

ABS-M30® for Fortus®

ABS-M30® workflow notes, compatibility, and how to evaluate cost-down options on Fortus® systems.

Read the ABS-M30® Fortus guide →ULTEM™ 9085 for Fortus® (guide + comparison)

Compatibility, workflow notes, and how Fortus® users evaluate 9085 options for production builds (including comparison-style breakdowns).

View the ULTEM™ 9085 page →PEKK for Fortus® (guide + buying path)

Overview for Fortus® users evaluating PEKK workflows, including independent supply and controlled deployment strategy.

Read the PEKK alternative guide →Run custom materials on Fortus® (parameter control guide)

The fastest path to “custom filament on Fortus®”: what parameter files do, what they control, and how to run stable custom profiles.

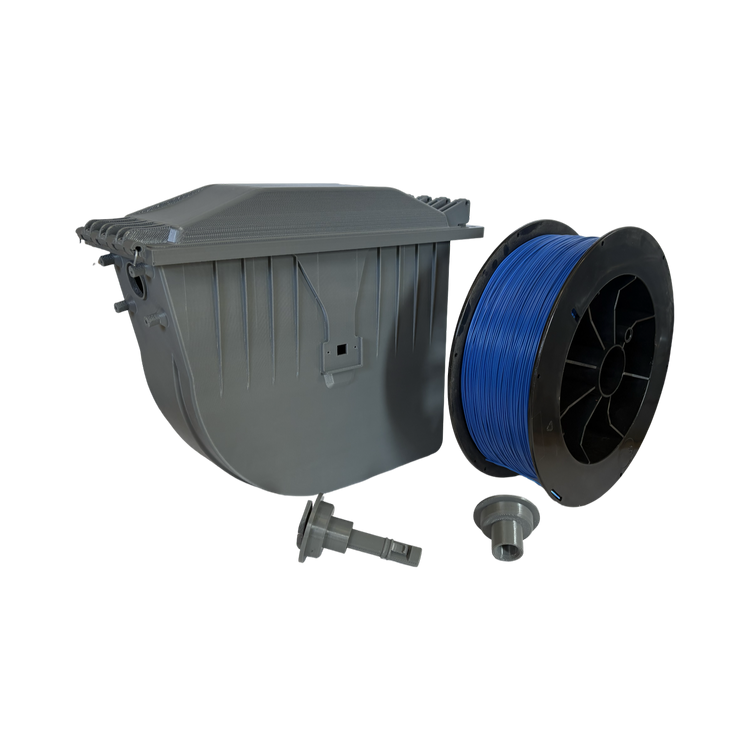

Materials for Stratasys® F123 Series

Model and support materials developed for Stratasys® F123 platforms, including F120, F170, F270, F370, and F770. This section is built around the material bay upgrade workflow, with additional resources coming as we roll out software unlock guidance for OEM and third-party materials.

Extrusion + Packaging

Precision diameter control and moisture-managed packaging using heat-sealed Mylar® barrier bags with desiccant — prepared for consistent results and simplified material handling.

F123 workflow focus

Designed around real F123 constraints — bay behavior, material handling, and repeatable prints. Built to support reliable day-to-day production output, not just one-off demos.

Roadmap: Unlock + Bay Upgrade

We’re building a full F123 ecosystem: unlock guidance, bay upgrade best practices, and material-specific setup notes. If you want to go “full fledge,” we’ll help you sequence it.

Popular resources for F123 users

F123 material bay upgrade

Guidance for moving beyond stock bay behavior — including recommended workflow, setup checks, and what to expect when expanding material options on F123 platforms.

Request the upgrade checklist →F123 software unlock (roadmap)

We’re building unlock guidance for OEM and third-party materials so you can run more options with confidence. Early customers can request onboarding now.

Get early access →Material recommendations (F123)

Not sure what to run on F120/F170/F270/F370/F770? Tell us your application and we’ll recommend model + support choices and a stability-first workflow.

Ask NEXT 3DP →